Single Board Computers (SBCs) have revolutionized the industrial landscape by offering compact, powerful, and versatile computing solutions. Among the various SBC architectures available, X86-based SBCs have emerged as the preferred choice for a wide range of industrial applications. In this blog post, we will explore the reasons behind the growing popularity of X86 SBCs in industries such as automotive, defense, medical, appliances, home applications, factory management, robotics, and more.

1. High Processing Power:

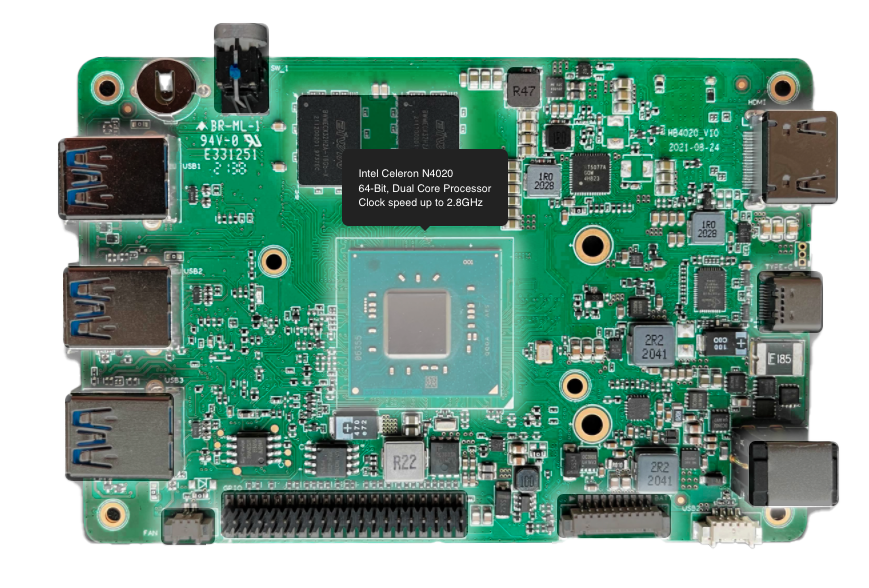

X86 processors, known for their robust performance and widespread compatibility, offer exceptional processing power to handle complex tasks encountered in industrial applications. Whether it’s running real-time algorithms in automotive systems, executing advanced simulations in defense applications, or powering medical imaging devices, X86 SBCs deliver the necessary horsepower for demanding industrial environments.

2. Broad Software and Hardware Support:

X86 SBCs benefit from extensive software and hardware compatibility, thanks to their longstanding presence in the market. They can seamlessly run a variety of operating systems, including Windows, Linux, and real-time operating systems (RTOS). This versatility simplifies software development, integration, and deployment across different industrial domains.

3. Peripheral Connectivity:

Industrial applications often require interfacing with diverse sensors, actuators, and control systems. X86 SBCs provide a wide range of peripheral connectivity options, including USB, Ethernet, serial ports, GPIO (General-Purpose Input/Output), and more. This enables seamless integration with existing industrial infrastructure and simplifies communication with external devices.

4. Extensive I/O Capabilities:

X86 SBCs offer a rich set of I/O capabilities crucial for industrial applications. They typically provide multiple high-speed interfaces, such as PCIe (Peripheral Component Interconnect Express), SATA (Serial ATA), and M.2 slots, facilitating the connection of storage devices, high-speed communication modules, and expansion cards. These capabilities are particularly beneficial for applications such as factory automation, robotics, and data-intensive tasks.

5. Robust and Reliable Design:

Industrial environments are often harsh, characterized by extreme temperatures, vibrations, and electrical noise. X86 SBCs designed for industrial applications are built to withstand these challenging conditions. They are equipped with rugged components, robust thermal management systems, and enhanced reliability features, ensuring consistent performance even in demanding scenarios.

6. Long-Term Availability and Support:

Industrial applications often have long product lifecycles, spanning several years or even decades. X86-based architectures have a proven track record of long-term availability and support, ensuring the longevity of industrial solutions. This stability is crucial for industries like automotive, defense, and medical, where legacy systems and long-term support are vital considerations.

7. Scalability and Flexibility:

X86 SBCs come in various form factors and configurations, allowing for scalability and flexibility in industrial applications. They can range from compact boards suitable for space-constrained environments to larger SBCs with expansion capabilities for demanding applications. This adaptability enables seamless integration into diverse industrial systems, offering room for growth and future upgrades.

X86 SBCs have established themselves as the go-to choice for a wide range of industrial applications, including automotive, defense, medical, appliances, home applications, factory management, robotics, and more. With their high processing power, extensive software and hardware support, peripheral connectivity, robust design, and long-term availability, X86 SBCs offer the reliability, performance, and scalability required in the demanding environments of industrial applications. As industries continue to evolve, X86 SBCs will undoubtedly play a significant role in shaping the future of industrial automation and innovation.

Recent Comments